The Uncertain Future of Independent Surfboard Shaping

Independent surfboard shapers are keeping the soul of surfing alive in a time dominated by big corporations. However, competing with machine shaping and massive budgets isn’t easy. For many shapers the challenge isn’t designing or shaping the board, it’s getting their boards into the hands of surfers willing to take a risk buying their product.

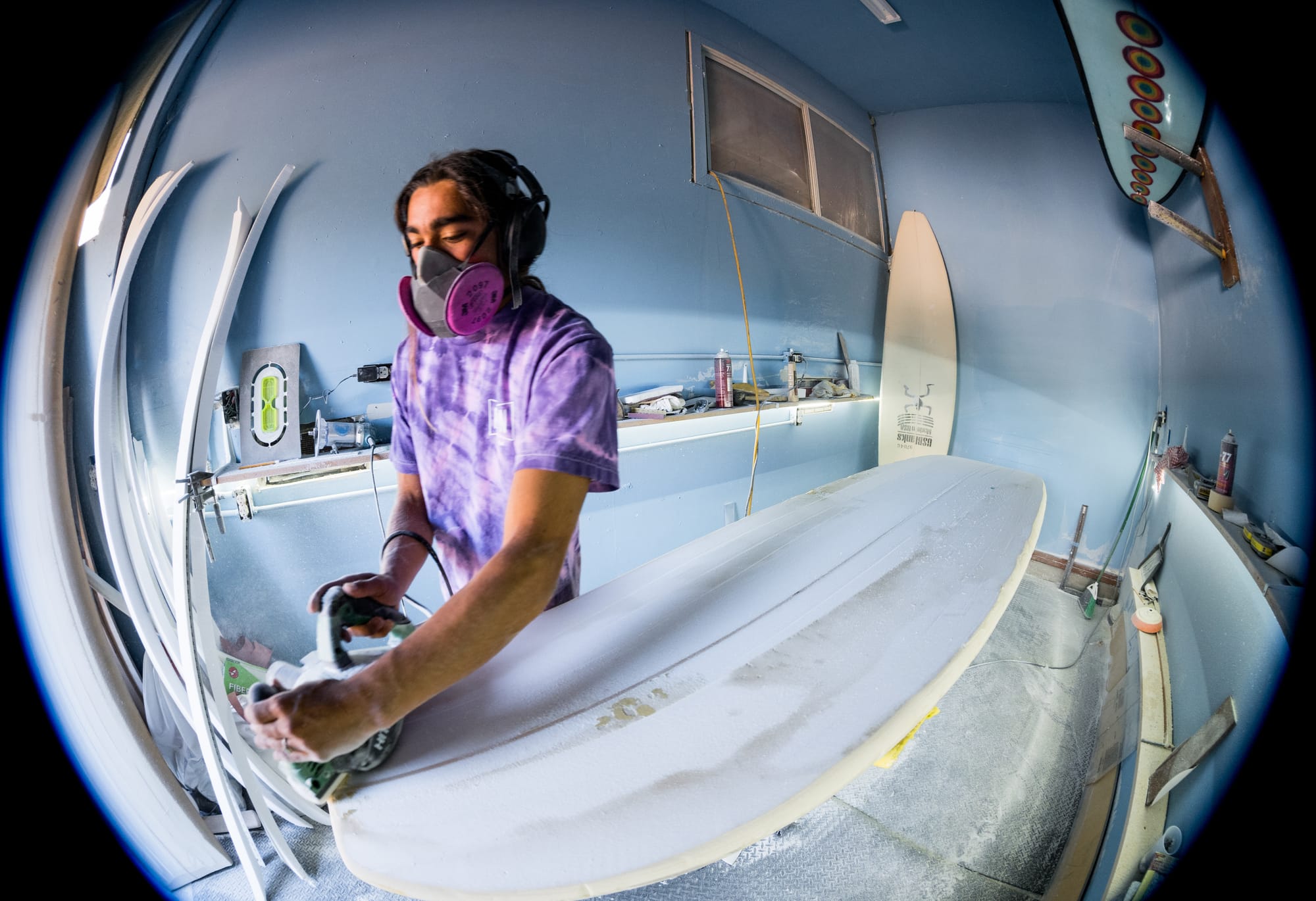

Revolutionary shapers like Gerry Lopez and Dick Brewer changed the world of surfing by building boards out of passion, not profit. Today, independent shapers are doing the same but are forced to compete with massive brands. For shapers like Zack Flores in Encinitas, California, the work is all about art, not business. “I see it as an art piece that functions doing something.” According to Flores, there are only up to five American shapers doing well enough to make a living. That being said, passion doesn’t pay the bills. A factory made board can be shipped from Mexico to San Diego for roughly the same price it costs to buy raw materials in California. This doesn’t include the hours it then takes to make the board. This is what makes it difficult for independent shapers to truly thrive in the industry.

Twenty years ago, it was cheaper to buy a blank and shape it in your garage than to buy a board off the rack at a shop. Today, the opposite is true. In small shaping bays across Southern California, the work is slow and physical. Since only a select few shapers are doing well and making a name for themselves, others are forced to work another job to make ends meet. For most, shaping isn’t their full-time career, rather it is a creative outlet they pursue in their free time. Making boards takes time, and custom orders are never guaranteed, especially today. For others, like Flores, they choose to have another job just because it makes sense. “I’d rather have another job that I do and make surfboards when I can.” “I’m more interested in the artistic side of it,” he said. It’s not all negative though. “Being an independent shaper is cool because you get to make your own stuff… the downside is that it’s just really frickin hard,” claimed Flores. As an independent shaper, there is no boss, shapers can make whatever they want, whenever they want. They have the freedom to experiment with different ideas and express themselves in the way of shaping. But, with the sheer cost of materials alone it’s hard to turn a profit, especially when almost every shop’s racks are filled with identical white boards.

It is hard to say where the independent surf industry is going. A major issue, aside from what it costs to shape, is supply and demand. Flores explained that with shops relying on cheaper imported boards, fewer orders make it to local shapers. Without a steady demand, many shapers struggle to get their boards out. He also mentioned how as a whole, the surfboard industry isn’t all that big. The scary reality is that surfers today just aren’t willing to spend more on a board when they can get one used from a shop for $400. Global brands can stock racks with consistent boards at a much lower price. This makes it very difficult to compete with big brands as an independent shaper. Flores said, “I wouldn’t be surprised if surfboard manufacturing as a whole shrunk down to maybe half of what it is right now.”

Surfboard shaping is an art. It’s not just a learned skill; it’s also having an eye for the board and the passion to create. Even with all of its challenges, independent shaping carries rewards that mass production cannot match. Flores described shaping as making a piece of art. He said, “There is a lot of the artistic side… you’re basically sculpting something and a lot of that is lost in the computer generated stuff.” Every board has a story, with independent shapers, no one board is the same. Like Flores said, it’s hard work and it doesn’t always come out the way you want. He talked about the excitement of when the board comes to life. “When one out of ten boards I’m making, which is something new, ends up working it’s really fun and exciting.” The upside of not being tied to a company is that shapers can follow their own ideas instead of repeating the same model over and over again. Each board isn’t just a reflection of the surfer it’s made for, but the vision of the shaper who brought it to life.

Independent shapers may never rival the profits of global surf brands, but they offer soul and art, which is something the industry cannot mass produce. Each board is different and represents something. The individuality of these shapers is what keeps the industry alive. Even as it becomes harder and harder to compete, the future of independent shaping is not measured in numbers, it’s measured in the boards that carve passion and art into the water.